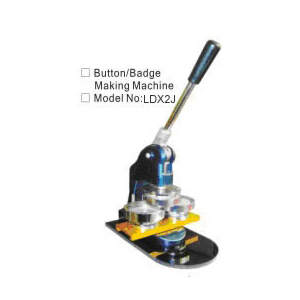

Model:LD-XZJ Specifications:

Volume:340*110*210mm Weight:5.5kg

Description:

Badge machine can produce different sizes of badges, bottle Kai, rope card, key chains, hand-foot key chain and so on ; and for the machine , here are many different moulds and pins, including round mould (25mm, 32mm, 44mm,58mm,75mm) , oval mould (35mm,55mm) a

Here are the detail information of the operation as follows ,

1) Mold handling methods:

1, take out pin;

2, the upper die hold up, bottom right mold and launch it;

3, two hands embracing energetically downward pressure on the upper die can be unloaded on the mold (the mold is to use ND magnet suck up to);

4, the mold should be filled with the body of the chain alignment pin slot, pushed up in order to prevail on the suction magnet;

5, the pin should be loaded for the next mold removal, through the fuselage to the left slide to advance to the next mold, this time will be entrusted on the mold so that the next film in the mold die block can pin on the left.

6, the pin wear.

2) Note:

The left driven by die skateboard, checking the ability to promote the film under the die block around on the mold pin rotation, the request of die left (right) on the mold when pushing Daotou left (right) rotate Daotou, and can the upper and lower die alignment, like the left (right) side of the closed mold with a hex wrench inside the mold a little Matsushita left (right) side of the screw, rotating die under its left (right) on the mold when pushing Daotou left (right) rotate Daotou and the upper and lower mold alignment until you can tighten the screws.

3) Usage:

1, the next mold slide pushed the left;

2, Iron Mask the mold on the left, concave down;

3, put the screen;

4, put a transparent film;

5, under the right skate to push Daotou mold;

6, plastic placed under the die at the end of the right (a certain pressure in the end), Planar upward (plastic at the end of the left turn poorly than 5mm);

7, grip the handle the machine, the next pressure on the mold, to the upper and lower mold folded up and lift the mold;

8, the next slide from left to push Daotou mold;

9, the next press machine handles, upper and lower dies close up can be (slightly energetically).

Video Demo

Video Demo